Understanding Nonwoven Fusible Interlining: A Key Component in Textile Innovation

Release time:

2025-09-20

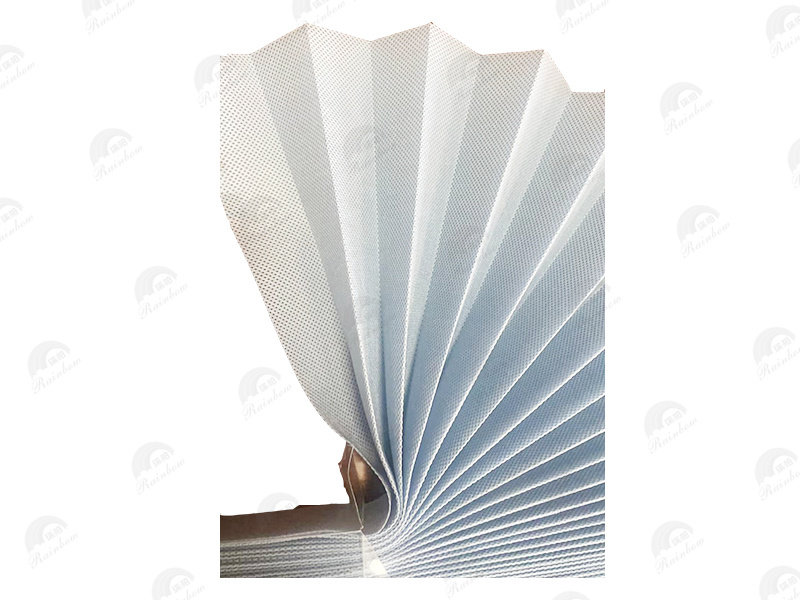

Nonwoven fusible interlining is a crucial component in the textile industry, particularly in the realm of garment manufacturing. This versatile material is made from fibers that are bonded together through various methods, rather than being woven, which allows for unique properties and applications. Understanding nonwoven fusible interlining can significantly enhance the quality and performance of garments, making it an essential topic for professionals in the textile sector.

One of the primary functions of nonwoven fusible interlining is to provide additional structure and support to fabrics. It is commonly used in areas such as collars, cuffs, and waistbands, where durability and shape retention are paramount. By applying heat and pressure, the fusible side of the interlining adheres to the outer fabric, creating a seamless bond that enhances the garment's overall integrity.

Nonwoven fusible interlining can be categorized into several types, including lightweight, medium-weight, and heavyweight options. Each type serves different purposes based on the fabric it is combined with and the desired end result. For instance, lightweight interlining is ideal for delicate fabrics, ensuring they maintain their drape without adding bulk. In contrast, heavyweight interlining provides the necessary structure for stiffer materials, ensuring that they hold their shape during wear.

Another notable benefit of nonwoven fusible interlining is its ability to improve the overall appearance of garments. By providing a smooth, even surface, it helps to prevent puckering and distortion, resulting in a polished finish. This is particularly important for high-end apparel, where attention to detail is crucial. Furthermore, nonwoven fusible interlining can also enhance the fabric's thermal properties, making garments more comfortable and functional for the wearer.

In addition to its structural and aesthetic advantages, nonwoven fusible interlining also contributes to the sustainability of textile production. Many manufacturers are now opting for eco-friendly materials and processes, which have led to the development of sustainable nonwoven options. These innovations not only reduce the environmental impact of garment production but also cater to the growing demand for sustainable fashion.

In summary, nonwoven fusible interlining is an invaluable material in the textile industry. Its ability to provide structure, improve appearance, and contribute to sustainability makes it a preferred choice among professionals in garment manufacturing. By understanding its properties and applications, industry experts can leverage nonwoven fusible interlining to enhance the quality and performance of their products, paving the way for innovation in fashion.

One of the primary functions of nonwoven fusible interlining is to provide additional structure and support to fabrics. It is commonly used in areas such as collars, cuffs, and waistbands, where durability and shape retention are paramount. By applying heat and pressure, the fusible side of the interlining adheres to the outer fabric, creating a seamless bond that enhances the garment's overall integrity.

Nonwoven fusible interlining can be categorized into several types, including lightweight, medium-weight, and heavyweight options. Each type serves different purposes based on the fabric it is combined with and the desired end result. For instance, lightweight interlining is ideal for delicate fabrics, ensuring they maintain their drape without adding bulk. In contrast, heavyweight interlining provides the necessary structure for stiffer materials, ensuring that they hold their shape during wear.

Another notable benefit of nonwoven fusible interlining is its ability to improve the overall appearance of garments. By providing a smooth, even surface, it helps to prevent puckering and distortion, resulting in a polished finish. This is particularly important for high-end apparel, where attention to detail is crucial. Furthermore, nonwoven fusible interlining can also enhance the fabric's thermal properties, making garments more comfortable and functional for the wearer.

In addition to its structural and aesthetic advantages, nonwoven fusible interlining also contributes to the sustainability of textile production. Many manufacturers are now opting for eco-friendly materials and processes, which have led to the development of sustainable nonwoven options. These innovations not only reduce the environmental impact of garment production but also cater to the growing demand for sustainable fashion.

In summary, nonwoven fusible interlining is an invaluable material in the textile industry. Its ability to provide structure, improve appearance, and contribute to sustainability makes it a preferred choice among professionals in garment manufacturing. By understanding its properties and applications, industry experts can leverage nonwoven fusible interlining to enhance the quality and performance of their products, paving the way for innovation in fashion.

Nonwoven fusible interlining

Previous Page

Previous Page

Latest News

Nantong Rainbow Nonwoven Tech Co.,Ltd.

Telephone:+86-13587673537

E-mail:chrislc717@163.com

Address: (No. 88, Sanzong South Road) Group 42, Xichansi Village, Xiting Town, Tongzhou District, Nantong City, Jiangsu Province

Copyright©2024 Nantong Rainbow Technology Co., Ltd. | Powered by www.300.cn

Copyright©2024 Nantong Rainbow Technology Co., Ltd.

Powered by www.300.cn