Understanding the Different Types of Woven Fusible Interlining: A Comprehensive Guide

Release time:

2025-09-19

Understanding the Different Types of Woven Fusible Interlining: A Comprehensive Guide

Table of Contents

- 1. Introduction to Woven Fusible Interlining

- 2. What is Fusible Interlining?

- 3. Benefits of Using Woven Fusible Interlining

- 4. Types of Woven Fusible Interlining

- 4.1 Lightweight Woven Fusible Interlining

- 4.2 Medium Weight Woven Fusible Interlining

- 4.3 Heavyweight Woven Fusible Interlining

- 5. Applications of Woven Fusible Interlining

- 6. How to Choose the Right Woven Fusible Interlining

- 7. Application Techniques for Woven Fusible Interlining

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Woven Fusible Interlining

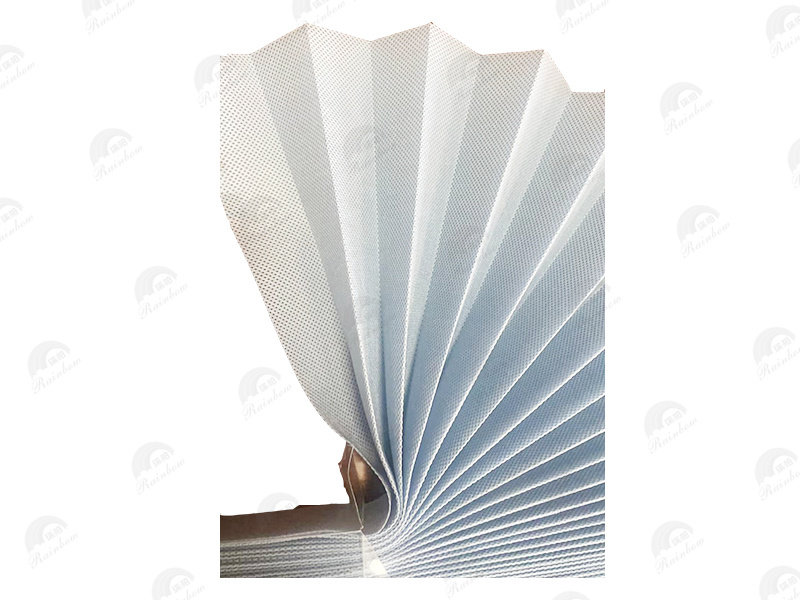

Woven fusible interlining plays a pivotal role in the world of textiles, transforming ordinary fabrics into structured, professional-looking garments. For designers and tailors alike, understanding the nuances of different types of woven fusible interlining is crucial. This guide will explore the various types available, their properties, applications, and more to help you make informed decisions in your sewing projects.

2. What is Fusible Interlining?

Fusible interlining is a type of interfacing that is engineered to bond with fabric when heat is applied. It consists of a layer of fabric, often coupled with a heat-activated adhesive on one side. This innovative design allows it to adhere seamlessly to the main fabric, providing additional structure and support. Woven fusible interlining is particularly popular due to its stability and versatility, making it ideal for a wide range of applications.

3. Benefits of Using Woven Fusible Interlining

Utilizing woven fusible interlining brings a multitude of advantages for sewing enthusiasts:

1. **Enhanced Structure**: Woven fusible interlining provides essential support, helping to maintain the shape of garments and accessories.

2. **Durability**: The strong bond created between the fabric and the interlining increases the lifespan of the finished product, ensuring it withstands wear and tear.

3. **Versatility**: Available in various weights and weaves, woven fusible interlining can be used with different fabric types, from lightweight silks to heavyweight wool.

4. **Improved Fit**: By adding stability to the fabric, it helps achieve a better fit, contributing to a more professional appearance in tailored garments.

5. **Ease of Use**: The fusible aspect simplifies the application process, eliminating the need for stitching down the interfacing.

4. Types of Woven Fusible Interlining

Choosing the right type of woven fusible interlining is essential for achieving desired results in your projects. Below, we break down the most common types based on weight and application.

4.1 Lightweight Woven Fusible Interlining

Lightweight woven fusible interlining is typically used for delicate fabrics, such as cotton lawn or lightweight silk. It provides a subtle support that does not compromise the drape and feel of the fabric. This type is excellent for shirts, blouses, and lining fabrics, ensuring they maintain their shape without becoming bulky.

4.2 Medium Weight Woven Fusible Interlining

Medium weight woven fusible interlining strikes a balance between support and flexibility. It is suitable for a range of fabrics, including cotton, polyester blends, and wool. This type is frequently used in tailored garments such as jackets and skirts, providing the necessary structure while allowing some movement.

4.3 Heavyweight Woven Fusible Interlining

Heavyweight woven fusible interlining is designed for robust fabrics such as denim, canvas, and heavy wool. This type offers maximum support and is ideal for structured garments like coats and tailored suits. It ensures the garment retains its shape and stands up to frequent use.

5. Applications of Woven Fusible Interlining

Woven fusible interlining is used in various applications across the fashion and textile industry:

- **Shirts and Blouses**: Adding interlining to collars and cuffs enhances their structure and longevity.

- **Jackets and Coats**: Interlining is crucial in providing shape and support, particularly in shoulders and lapels.

- **Pants and Skirts**: It helps maintain the desired fit and structure, particularly in waistbands and hems.

- **Accessories**: Items such as bags and hats benefit from the added support, ensuring they hold their shape.

6. How to Choose the Right Woven Fusible Interlining

Selecting the appropriate woven fusible interlining involves assessing several factors:

1. **Fabric Type**: Consider the weight and composition of your primary fabric. Lightweight interlining works best with delicate fabrics, while heavier options are suited for robust materials.

2. **Project Purpose**: Determine the garment’s function. For structured pieces, opt for heavyweight interlining, while for more fluid designs, lightweight varieties are preferable.

3. **Adhesive Quality**: Inspect the adhesive properties of the interlining. High-quality fusibles will provide a strong bond without compromising the fabric’s integrity.

4. **Pre-Wash Compatibility**: Ensure that the interlining is compatible with your fabric's care instructions, especially if pre-washing is necessary.

7. Application Techniques for Woven Fusible Interlining

Applying woven fusible interlining correctly is vital for achieving optimal results. Here are some techniques to ensure a successful application:

1. **Preparation**: Before application, pre-wash both the fabric and interlining to prevent any shrinkage after the garment is finished.

2. **Alignment**: Place the adhesive side of the interlining against the wrong side of the fabric, ensuring it aligns properly.

3. **Heat Setting**: Using a pressing cloth, apply heat with an iron set to the recommended temperature for the interlining. Press down firmly for the specified duration to ensure a secure bond.

4. **Cooling**: Allow the fabric to cool completely before handling to ensure the adhesive sets properly.

5. **Sewing Techniques**: When sewing, use a longer stitch length to avoid puckering and ensure smooth seams.

8. Frequently Asked Questions

1. Can I use woven fusible interlining on all types of fabric?

Yes, but it’s essential to match the weight of the interlining with the fabric type to achieve the best results.

2. How do I know if my fusible interlining is of good quality?

Quality fusible interlining will have a strong adhesive that bonds well without causing damage to your fabric.

3. Is it necessary to pre-wash interlining?

Pre-washing is recommended to prevent shrinkage and ensure compatibility with your fabric.

4. Can I sew through fusible interlining?

Yes, you can sew through it, but use a longer stitch length to avoid puckering.

5. What should I do if the interlining does not adhere properly?

Reapply heat, ensuring you use the appropriate temperature and pressing duration to achieve a strong bond.

9. Conclusion

Understanding the different types of woven fusible interlining is essential for any sewing enthusiast. By familiarizing yourself with the various types, their applications, and proper techniques, you can make informed choices that greatly enhance the quality of your projects. The right interlining not only improves the structure and fit of garments but also elevates your overall sewing experience. Embrace the benefits of woven fusible interlining, and watch your sewing creations transform into professional-quality pieces.

woven fusible interlining

Latest News

Nantong Rainbow Nonwoven Tech Co.,Ltd.

Telephone:+86-13587673537

E-mail:chrislc717@163.com

Address: (No. 88, Sanzong South Road) Group 42, Xichansi Village, Xiting Town, Tongzhou District, Nantong City, Jiangsu Province

Copyright©2024 Nantong Rainbow Technology Co., Ltd. | Powered by www.300.cn

Copyright©2024 Nantong Rainbow Technology Co., Ltd.

Powered by www.300.cn