Understanding GRS Nonwoven Fabric: An Eco-Friendly Textile Revolution

Release time:

2025-09-18

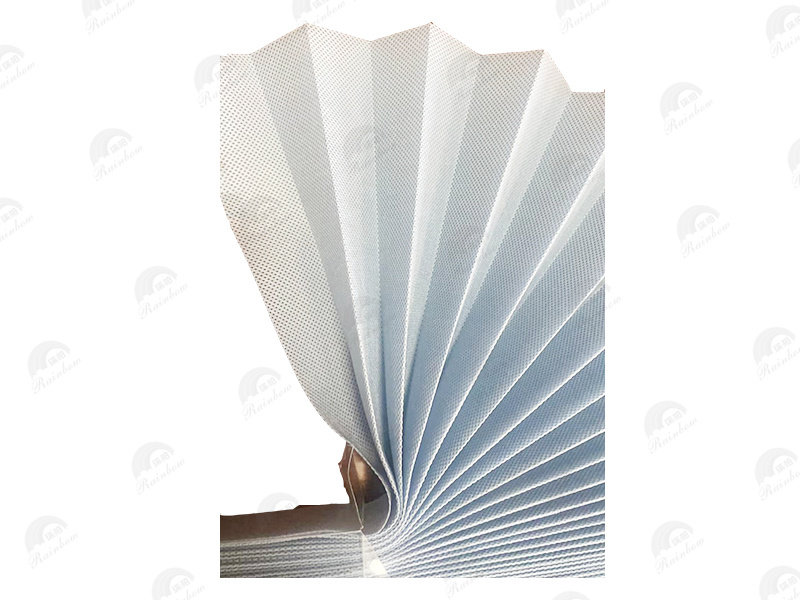

GRS nonwoven fabric, short for Global Recycled Standard nonwoven fabric, represents a significant step forward in the textile industry, particularly in the realm of environmentally friendly materials. This innovative fabric is created from recycled materials, which means it contributes to reducing waste and promoting sustainability. The GRS certification ensures that the fabric meets stringent criteria regarding recycled content and environmental practices, making it a responsible choice for manufacturers and consumers alike.

One of the most notable characteristics of GRS nonwoven fabric is its versatility. It can be engineered to fulfill various functions based on the type of fibers used and the manufacturing process. Common applications include hygiene products, medical textiles, geotextiles, and even apparel. The ability to tailor the fabric for specific uses makes it an appealing choice for various industries striving for both performance and sustainability.

The production of GRS nonwoven fabric typically involves processes that do not require weaving or knitting, which contributes to its unique structure. Instead, fibers are bonded together through mechanical, thermal, or chemical means. This process not only results in a fabric that is lightweight and breathable but also one that possesses excellent durability. Consequently, GRS nonwoven fabric can withstand the rigors of daily use while maintaining its functional properties.

From an environmental perspective, the adoption of GRS nonwoven fabric is a game-changer. By utilizing recycled fibers, it helps reduce the demand for virgin materials, thus lessening the overall carbon footprint associated with textile production. Moreover, the GRS certification process encourages manufacturers to implement responsible practices throughout their supply chains, promoting a more sustainable approach to production.

Beyond its ecological benefits, GRS nonwoven fabric also aligns with the growing consumer demand for transparency and ethical sourcing. As more individuals and businesses seek to minimize their environmental impact, materials like GRS nonwoven fabric are becoming increasingly sought after. Utilizing such fabrics not only enhances a brand's image but also fosters consumer loyalty among environmentally conscious shoppers.

In conclusion, GRS nonwoven fabric stands at the forefront of an eco-friendly textile revolution. With its unique properties, diverse applications, and significant environmental benefits, it offers a sustainable solution for industries aiming to make a positive impact. Investing in GRS nonwoven fabric is not only a step towards achieving sustainability but also a commitment to quality and innovation in the textile sector. Embracing such materials paves the way for a greener future in textiles, encouraging both manufacturers and consumers to make responsible choices.

One of the most notable characteristics of GRS nonwoven fabric is its versatility. It can be engineered to fulfill various functions based on the type of fibers used and the manufacturing process. Common applications include hygiene products, medical textiles, geotextiles, and even apparel. The ability to tailor the fabric for specific uses makes it an appealing choice for various industries striving for both performance and sustainability.

The production of GRS nonwoven fabric typically involves processes that do not require weaving or knitting, which contributes to its unique structure. Instead, fibers are bonded together through mechanical, thermal, or chemical means. This process not only results in a fabric that is lightweight and breathable but also one that possesses excellent durability. Consequently, GRS nonwoven fabric can withstand the rigors of daily use while maintaining its functional properties.

From an environmental perspective, the adoption of GRS nonwoven fabric is a game-changer. By utilizing recycled fibers, it helps reduce the demand for virgin materials, thus lessening the overall carbon footprint associated with textile production. Moreover, the GRS certification process encourages manufacturers to implement responsible practices throughout their supply chains, promoting a more sustainable approach to production.

Beyond its ecological benefits, GRS nonwoven fabric also aligns with the growing consumer demand for transparency and ethical sourcing. As more individuals and businesses seek to minimize their environmental impact, materials like GRS nonwoven fabric are becoming increasingly sought after. Utilizing such fabrics not only enhances a brand's image but also fosters consumer loyalty among environmentally conscious shoppers.

In conclusion, GRS nonwoven fabric stands at the forefront of an eco-friendly textile revolution. With its unique properties, diverse applications, and significant environmental benefits, it offers a sustainable solution for industries aiming to make a positive impact. Investing in GRS nonwoven fabric is not only a step towards achieving sustainability but also a commitment to quality and innovation in the textile sector. Embracing such materials paves the way for a greener future in textiles, encouraging both manufacturers and consumers to make responsible choices.

GRS Nonwoven Fabric

Latest News

Nantong Rainbow Nonwoven Tech Co.,Ltd.

Telephone:+86-13587673537

E-mail:chrislc717@163.com

Address: (No. 88, Sanzong South Road) Group 42, Xichansi Village, Xiting Town, Tongzhou District, Nantong City, Jiangsu Province

Copyright©2024 Nantong Rainbow Technology Co., Ltd. | Powered by www.300.cn

Copyright©2024 Nantong Rainbow Technology Co., Ltd.

Powered by www.300.cn