Choosing the Right Type of Chemical Bonded Nonwoven Interlining for Your Needs

Release time:

2025-09-17

Choosing the Right Type of Chemical Bonded Nonwoven Interlining for Your Needs

Table of Contents

- 1. Introduction to Chemical Bonded Nonwoven Interlining

- 2. Understanding Nonwoven Interlining

- 3. Benefits of Chemical Bonded Nonwoven Interlining

- 4. How to Choose the Right Chemical Bonded Nonwoven Interlining

- 5. Application Areas of Chemical Bonded Nonwoven Interlining

- 6. Expert Tips for Selecting Nonwoven Interlining

- 7. Frequently Asked Questions

- 8. Conclusion

1. Introduction to Chemical Bonded Nonwoven Interlining

In the textile industry, the selection of materials significantly impacts the quality and durability of finished products. **Chemical bonded nonwoven interlining** stands out as a popular choice among manufacturers due to its unique properties and versatility. Understanding the various types and their specific applications can help you make an informed decision that enhances your products.

2. Understanding Nonwoven Interlining

Nonwoven interlining is a fabric made by bonding fibers together using mechanical, thermal, or chemical processes. This innovative fabric serves as a stabilizing layer, providing structure and support to garments, accessories, and other textile products.

2.1 What is Nonwoven Material?

Nonwoven materials are produced through a process that eliminates the need for traditional weaving or knitting. Instead, fibers are directly bonded together, creating a fabric that can be tailored to specific requirements. The result is a fabric that offers unique benefits, such as enhanced durability and lower production costs.

2.2 Types of Nonwoven Interlining

There are various types of nonwoven interlining, predominantly categorized by their bonding techniques:

1. **Chemical Bonded Nonwoven**: This type uses adhesives to bond the fibers, resulting in a strong and stable fabric.

2. **Thermal Bonded Nonwoven**: Fibers are fused using heat, offering a soft hand and good drape.

3. **Mechanical Bonded Nonwoven**: This method relies on needle punching or hydroentangling to bond fibers, producing a durable fabric.

Understanding these types is essential for selecting the right interlining for your needs.

3. Benefits of Chemical Bonded Nonwoven Interlining

Chemical bonded nonwoven interlining offers numerous advantages that contribute to its popularity in the textile industry.

3.1 Durability and Strength

One of the standout features of chemical bonded nonwoven interlining is its **exceptional durability**. The chemical bonding process creates a strong fabric that withstands wear and tear, making it ideal for garments that undergo frequent washing and use.

3.2 Cost-Effectiveness

Cost is a crucial factor in textile production. Chemical bonded nonwoven interlining typically requires less material and labor than woven alternatives, leading to significant cost savings. Its long-lasting properties further enhance its cost-effectiveness, as it reduces the need for frequent replacements.

3.3 Versatility in Applications

This type of interlining is incredibly versatile, finding applications in various sectors, including fashion, home textiles, and automotive fabrics. It can be used for shirts, jackets, skirts, and even upholstery, providing excellent support without adding bulk.

4. How to Choose the Right Chemical Bonded Nonwoven Interlining

Choosing the right chemical bonded nonwoven interlining involves several considerations to ensure it meets your specific needs.

4.1 Considering Fabric Type

The type of fabric you are working with plays a significant role in your choice of interlining. For delicate fabrics like silk, a lightweight, softer interlining is recommended to avoid compromising the drape and feel. Conversely, heavier fabrics like denim may benefit from a sturdier interlining to maintain structure.

4.2 Assessing Weight and Thickness

Weight and thickness are critical factors that affect the hand feel and performance of the final garment. When selecting interlining, consider the weight of the outer fabric and choose an interlining that complements it. A balanced approach ensures both aesthetics and functionality.

4.3 Evaluating the Application

Different applications may require specific properties from the interlining. For instance, garments intended for high-stress areas, such as collars and cuffs, may need a more robust interlining, while lighter applications like linings may benefit from a soft, flexible option.

5. Application Areas of Chemical Bonded Nonwoven Interlining

Chemical bonded nonwoven interlining is used across various industries, including:

- **Fashion and Apparel**: Reinforcing collars, cuffs, and waistbands in garments.

- **Home Textiles**: Providing stability in curtains, upholstery, and bedding.

- **Automotive Textiles**: Enhancing the durability and aesthetics of car interiors.

Each application requires a tailored approach, making it essential to understand the specific interlining characteristics that best suit your project.

6. Expert Tips for Selecting Nonwoven Interlining

When selecting chemical bonded nonwoven interlining, consider the following expert tips:

1. **Conduct Fabric Testing**: Before making a large purchase, test samples to evaluate how they perform with your specific fabrics and applications.

2. **Consult with Suppliers**: Engage with knowledgeable suppliers who can provide insights and recommendations based on your project requirements.

3. **Stay Informed on Industry Trends**: The textile industry is constantly evolving. Keeping abreast of the latest developments can help you make informed decisions about the types of interlining available.

7. Frequently Asked Questions

What is the main difference between woven and nonwoven interlining?

The primary difference lies in their construction. Woven interlining is created by interlacing threads, while nonwoven interlining is made by bonding fibers together. Nonwoven interlining typically offers better flexibility and is often lighter.

Can chemical bonded nonwoven interlining be washed?

Yes, chemical bonded nonwoven interlining is generally washable. However, it is essential to follow the specific care instructions provided by the manufacturer to maintain its integrity.

How do I know which type of nonwoven is right for my project?

Selecting the right type depends on several factors, including the fabric type, application, and desired characteristics, such as stiffness or flexibility. Testing samples can also aid in making the right choice.

Is chemical bonded interlining environmentally friendly?

While many chemical bonded nonwoven products are made from synthetic materials, there are eco-friendly alternatives available. It’s best to consult with suppliers about sustainable options if environmental impact is a concern.

Can I use nonwoven interlining for outerwear?

Absolutely. Chemical bonded nonwoven interlining is suitable for outerwear, providing structure and warmth without adding significant weight. Choose heavier options for colder climates.

8. Conclusion

Selecting the right type of chemical bonded nonwoven interlining is crucial for achieving high-quality textile products. By understanding the characteristics and benefits of various interlining types, considering fabric compatibility, and evaluating application needs, you can make an informed choice that enhances your projects. With the right interlining, your garments will not only look great but also stand the test of time, offering durability and excellent performance.

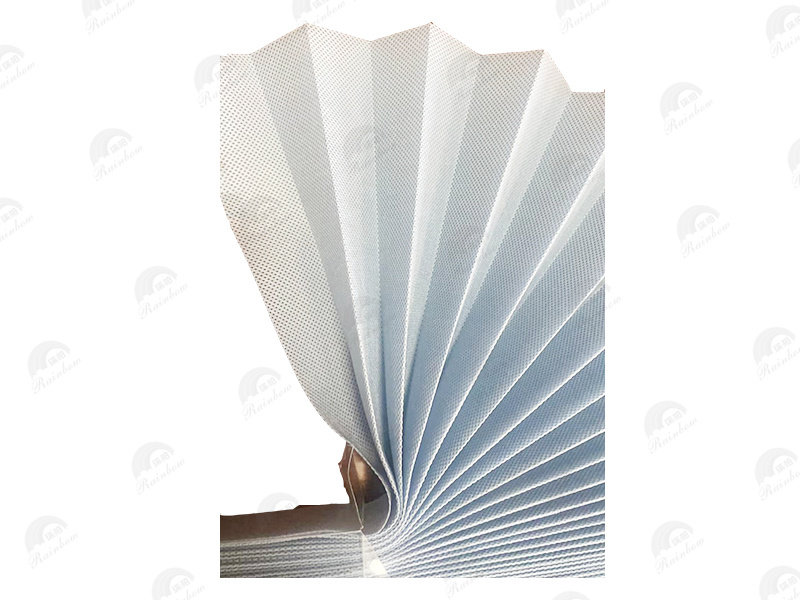

chemical bonded nonwoven interlining fabric

Latest News

Nantong Rainbow Nonwoven Tech Co.,Ltd.

Telephone:+86-13587673537

E-mail:chrislc717@163.com

Address: (No. 88, Sanzong South Road) Group 42, Xichansi Village, Xiting Town, Tongzhou District, Nantong City, Jiangsu Province

Copyright©2024 Nantong Rainbow Technology Co., Ltd. | Powered by www.300.cn

Copyright©2024 Nantong Rainbow Technology Co., Ltd.

Powered by www.300.cn