Understanding Chemical Bonded Nonwoven Fusible Interlining: A Key Component in Textile Applications

Release time:

2025-07-12

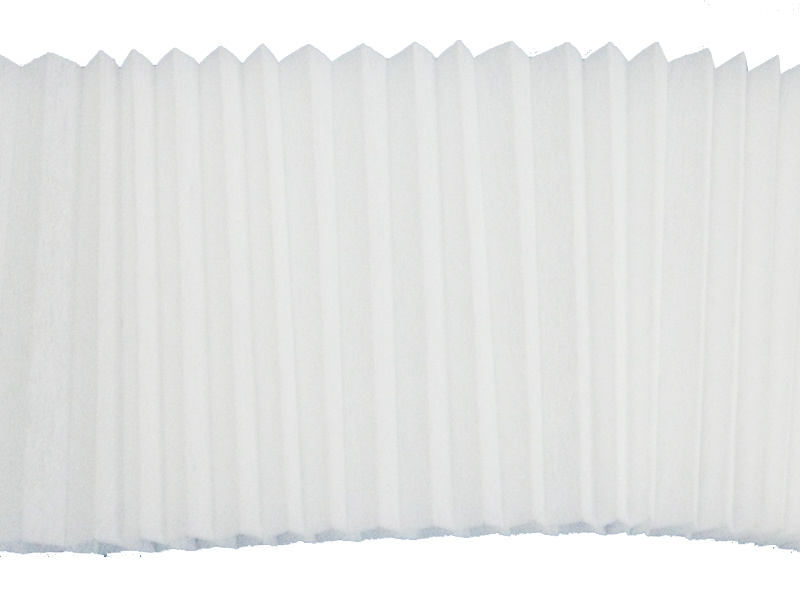

Chemical bonded nonwoven fusible interlining is an innovative textile material widely used in the garment industry to improve the structure and durability of fabrics. This type of interlining is produced by bonding fibers together using a chemical process, which creates a strong, flexible, and lightweight fabric that can be easily fused to the main garment fabric. The unique properties of chemical bonded nonwoven fusible interlining make it an essential choice for various applications in clothing production.

One of the primary advantages of chemical bonded nonwoven fusible interlining is its excellent adhesion properties. When heat is applied, the fusible side of the interlining melts and adheres firmly to the fabric, providing a stable and long-lasting bond. This property is particularly beneficial for enhancing the shape and structure of garments, such as collars, cuffs, and waistbands. Moreover, the lightweight nature of this interlining ensures that garments maintain a comfortable feel while enhancing their overall appearance.

In addition to its structural benefits, chemical bonded nonwoven fusible interlining also offers a range of functional advantages. For instance, it can help in achieving better drape and reducing fabric distortion during wear and washing. This is especially important for delicate fabrics that may easily lose their intended shape over time. Furthermore, this type of interlining is often designed to be breathable, allowing moisture to escape, which enhances the comfort of the final garment.

The versatility of chemical bonded nonwoven fusible interlining allows it to be used across various textile applications. It is suitable for both lightweight and heavier fabrics, making it ideal for a wide range of clothing items, including formal wear, outerwear, and sportswear. Additionally, it can be utilized in home textiles, such as curtains and upholstery, where a neat finish and structural integrity are also essential.

When selecting chemical bonded nonwoven fusible interlining, it is crucial to consider factors such as the type of fabric it will be paired with, the intended use of the garment, and the desired level of stiffness or softness. By choosing the right type of interlining, manufacturers and designers can ensure that their final products not only look great but also function effectively and stand the test of time.

In conclusion, chemical bonded nonwoven fusible interlining plays a pivotal role in the textile industry by enhancing the quality, structure, and performance of garments. Its unique properties make it a preferred choice for many applications, ensuring that clothing maintains its intended look and feel. As the demand for high-quality fabrics continues to rise, understanding the benefits and applications of this interlining becomes increasingly important for industry professionals.

One of the primary advantages of chemical bonded nonwoven fusible interlining is its excellent adhesion properties. When heat is applied, the fusible side of the interlining melts and adheres firmly to the fabric, providing a stable and long-lasting bond. This property is particularly beneficial for enhancing the shape and structure of garments, such as collars, cuffs, and waistbands. Moreover, the lightweight nature of this interlining ensures that garments maintain a comfortable feel while enhancing their overall appearance.

In addition to its structural benefits, chemical bonded nonwoven fusible interlining also offers a range of functional advantages. For instance, it can help in achieving better drape and reducing fabric distortion during wear and washing. This is especially important for delicate fabrics that may easily lose their intended shape over time. Furthermore, this type of interlining is often designed to be breathable, allowing moisture to escape, which enhances the comfort of the final garment.

The versatility of chemical bonded nonwoven fusible interlining allows it to be used across various textile applications. It is suitable for both lightweight and heavier fabrics, making it ideal for a wide range of clothing items, including formal wear, outerwear, and sportswear. Additionally, it can be utilized in home textiles, such as curtains and upholstery, where a neat finish and structural integrity are also essential.

When selecting chemical bonded nonwoven fusible interlining, it is crucial to consider factors such as the type of fabric it will be paired with, the intended use of the garment, and the desired level of stiffness or softness. By choosing the right type of interlining, manufacturers and designers can ensure that their final products not only look great but also function effectively and stand the test of time.

In conclusion, chemical bonded nonwoven fusible interlining plays a pivotal role in the textile industry by enhancing the quality, structure, and performance of garments. Its unique properties make it a preferred choice for many applications, ensuring that clothing maintains its intended look and feel. As the demand for high-quality fabrics continues to rise, understanding the benefits and applications of this interlining becomes increasingly important for industry professionals.

chemical bonded Nonwoven fusible interlining

Previous Page

Previous Page

Latest News

Nantong Rainbow Technology Co., Ltd.

Telephone:+86-13587673537

E-mail:chrislc717@163.com

Address: Group 42, Xizansi Village, Xiting Town, Tongzhou District, Nantong City, Jiangsu Province

Copyright©2024 Nantong Rainbow Technology Co., Ltd. | Powered by www.300.cn

Copyright©2024 Nantong Rainbow Technology Co., Ltd.

Powered by www.300.cn