Understanding Fusible Nonwoven Interlining: A Comprehensive Guide for Textile Professionals

Release time:

2025-07-11

Understanding Fusible Nonwoven Interlining: A Comprehensive Guide

Table of Contents

1. Introduction to Fusible Nonwoven Interlining

2. What is Fusible Nonwoven Interlining?

3. Types of Fusible Nonwoven Interlining

3.1 Light Weight vs. Heavy Weight Interlining

3.2 Different Adhesive Coatings

4. Applications of Fusible Nonwoven Interlining

4.1 Fashion Apparel

4.2 Home Textiles

4.3 Technical Textiles

5. Benefits of Using Fusible Nonwoven Interlining

6. How to Choose the Right Fusible Nonwoven Interlining

6.1 Considerations for Fabric Types

6.2 Purpose and Functionality

7. Application Techniques and Best Practices

7.1 Heat Application Methods

7.2 Common Mistakes to Avoid

8. FAQs About Fusible Nonwoven Interlining

9. Conclusion

1. Introduction to Fusible Nonwoven Interlining

Fusible nonwoven interlining is an essential component in the textile industry, particularly for garment construction and design. This specialized material enhances the structure and quality of fabrics, making it a vital ingredient in fashion and apparel production. In this comprehensive guide, we will explore the various aspects of fusible nonwoven interlining, including its types, applications, and benefits, along with practical tips for its effective use.

2. What is Fusible Nonwoven Interlining?

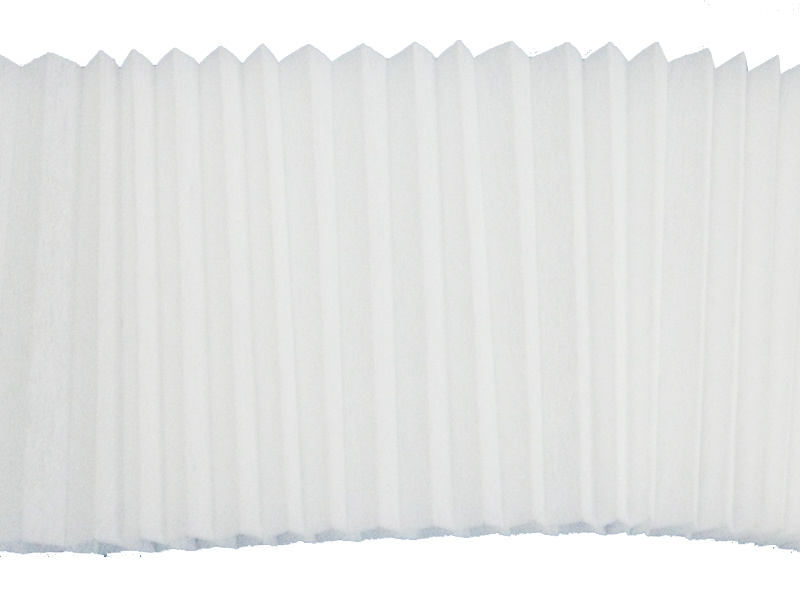

Fusible nonwoven interlining is a type of fabric that is made by bonding fibers together without weaving. It is coated with a heat-activated adhesive on one side, allowing it to bond permanently to the fabric when heat is applied. This material provides additional support, stability, and shape retention to garments, making it a popular choice among textile professionals.

3. Types of Fusible Nonwoven Interlining

Understanding the different types of fusible nonwoven interlining is crucial for selecting the right one for your project.

3.1 Light Weight vs. Heavy Weight Interlining

Lightweight fusible nonwoven interlining is typically used for delicate fabrics, providing minimal structure while enhancing drape. This is ideal for blouses, linings, and lightweight garments. Conversely, heavy weight interlining offers substantial support and shape retention, making it suitable for structured garments like jackets and coats.

3.2 Different Adhesive Coatings

The adhesive used on fusible nonwoven interlining can vary significantly. Some common types include:

- **Polyamide Adhesive**: Provides a strong bond and is often used for heavier fabrics.

- **Polyester Adhesive**: Suitable for lighter fabrics and offers good flexibility.

- **Water-Soluble Adhesive**: Ideal for temporary applications where the interlining needs to be removed after use.

4. Applications of Fusible Nonwoven Interlining

Fusible nonwoven interlining finds its applications across various sectors in textiles, including:

4.1 Fashion Apparel

In fashion, fusible nonwoven interlining is predominantly used to reinforce collars, cuffs, and waistbands. It enhances the shape and provides a polished finish, ensuring garments look professional and well-constructed.

4.2 Home Textiles

In home textiles, fusible nonwoven interlining can be found in curtains, upholstery, and bed linens. It adds durability and structure to these items, making them more functional and aesthetically pleasing.

4.3 Technical Textiles

Fusible nonwoven interlining is also utilized in technical textiles for applications requiring specific functionalities, such as moisture management, insulation, and breathability, catering to industries like sportswear and outdoor clothing.

5. Benefits of Using Fusible Nonwoven Interlining

The advantages of incorporating fusible nonwoven interlining into your textile projects are numerous:

- **Improved Fabric Stability**: It provides additional support to fabrics, preventing stretching and distortion.

- **Enhanced Durability**: The bond created during heat activation increases the lifespan of the garment.

- **Versatility**: Available in various weights and adhesive types, it can be used across different applications.

- **Ease of Use**: Fusible interlining simplifies the sewing process by eliminating the need for additional stitching.

6. How to Choose the Right Fusible Nonwoven Interlining

Selecting the appropriate fusible nonwoven interlining requires careful consideration of several factors:

6.1 Considerations for Fabric Types

Match the interlining to the fabric type for optimal results. For instance, lightweight interlining works best with delicate fabrics, while heavy-duty interlining is ideal for sturdier materials like denim and canvas.

6.2 Purpose and Functionality

Identify the intended use of the garment. For structured pieces, choose a heavier interlining, whereas for softer silhouettes, opt for lighter options to maintain drape.

7. Application Techniques and Best Practices

Effectively applying fusible nonwoven interlining is key to achieving the desired results.

7.1 Heat Application Methods

The most common method of applying fusible nonwoven interlining is through an iron. Set the iron to the appropriate temperature for the fabric and press down firmly for a few seconds, allowing the adhesive to activate. Always use a pressing cloth to protect the fabric.

7.2 Common Mistakes to Avoid

Avoid these common pitfalls to ensure successful application:

- Not pre-washing fabrics can lead to shrinkage and distortion post-application.

- Insufficient heat or pressure may result in a weak bond.

- Failing to test on a scrap fabric can cause damage if the heat settings are incorrect.

8. FAQs About Fusible Nonwoven Interlining

1. Can fusible nonwoven interlining be washed?

Yes, most fusible nonwoven interlining can withstand washing. However, it's crucial to follow the manufacturer's instructions for care to maintain the integrity of the bond.

2. How do I know which weight of interlining to choose?

The weight of interlining should correspond to the weight of the fabric. Lighter fabrics require lighter interlining, while heavier fabrics benefit from more robust options.

3. Is fusible nonwoven interlining suitable for all types of fabrics?

While fusible nonwoven interlining works well with most fabrics, delicate or heat-sensitive materials may require special consideration. Always perform a test run on a scrap piece before applying.

4. Can I use fusible nonwoven interlining for quilting?

Yes, fusible nonwoven interlining can be used in quilting to add structure. However, ensure that the adhesive is compatible with quilting techniques.

5. What should I do if the interlining doesn’t stick?

If the interlining does not adhere properly, check the temperature settings of your iron, ensure you are using a pressing cloth, and apply enough pressure during the bonding process.

9. Conclusion

In conclusion, fusible nonwoven interlining is an indispensable resource in the textile industry that enhances garment structure, durability, and appearance. Understanding its types, applications, and best practices can significantly improve your sewing and design outcomes. By carefully selecting the right type of interlining and applying it correctly, you can achieve professional-quality results in your textile projects. Whether you are working on fashion apparel, home textiles, or technical fabrics, fusible nonwoven interlining is a key player in elevating the quality and longevity of your creations.

fusible nonwoven interlining

Latest News

Nantong Rainbow Technology Co., Ltd.

Telephone:+86-13587673537

E-mail:chrislc717@163.com

Address: Group 42, Xizansi Village, Xiting Town, Tongzhou District, Nantong City, Jiangsu Province

Copyright©2024 Nantong Rainbow Technology Co., Ltd. | Powered by www.300.cn

Copyright©2024 Nantong Rainbow Technology Co., Ltd.

Powered by www.300.cn