Exploring the Cost Benefits of Foam Bonded Nonwoven Lining in Production

Release time:

2025-07-09

Exploring the Cost Benefits of Foam Bonded Nonwoven Lining in Production

Table of Contents

- Introduction to Foam Bonded Nonwoven Lining

- What is Nonwoven Fabric?

- Understanding the Foam Bonding Process

- Advantages of Foam Bonded Nonwoven Lining

- Cost Efficiency in Production

- Applications in Various Industries

- Sustainability Aspect of Foam Bonded Nonwoven

- The Future of Nonwoven Fabrics

- Conclusion

- FAQs

Introduction to Foam Bonded Nonwoven Lining

The textile industry is constantly evolving, and with advancements in technology, the production of nonwoven fabrics has become increasingly significant. Among these innovations, **foam bonded nonwoven lining** has emerged as a versatile and cost-effective solution for manufacturers. This article explores the numerous cost benefits associated with foam bonded nonwoven lining, shedding light on its applications and advantages.

What is Nonwoven Fabric?

Nonwoven fabrics are textiles made from fibers that are bonded together through various methods, including heat, chemicals, or mechanical means. Unlike traditional woven or knitted fabrics, nonwoven materials are engineered to fulfill specific functions, making them a popular choice across multiple industries. They are lightweight, durable, and can be tailored to meet the unique needs of different applications.

The Role of Foam in Nonwoven Fabrics

Foam bonded nonwoven fabrics incorporate a layer of foam into the bonding process. This not only enhances the fabric’s performance characteristics, such as softness and flexibility, but also provides additional insulation and cushioning properties. The incorporation of foam significantly broadens the usage spectrum of nonwoven fabrics in sectors ranging from automotive to healthcare.

Understanding the Foam Bonding Process

The foam bonding process involves several critical steps. Initially, the fibers are laid out in a desired pattern, followed by the application of a foam layer. Through a combination of heat and pressure, the foam is bonded to the fibers, creating a cohesive fabric that retains the beneficial properties of both materials. This method ensures a strong, durable, and lightweight fabric suitable for various applications.

Key Components of Foam Bonding

- **Fiber Selection:** The choice of fibers impacts the final product's strength and texture.

- **Foam Characteristics:** Different types of foam can be utilized to achieve specific qualities, such as density and resilience.

- **Bonding Technique:** The method of applying heat and pressure affects the overall performance of the nonwoven fabric.

Advantages of Foam Bonded Nonwoven Lining

Foam bonded nonwoven lining offers numerous advantages that make it an attractive option for manufacturers.

Enhanced Performance

One of the primary benefits is the **enhanced performance** characteristics of the fabric. The integration of foam provides added cushioning, which is particularly advantageous in applications like automotive interiors and upholstery. This results in products that not only perform better but also offer improved comfort.

Cost-Effectiveness

The production of foam bonded nonwoven lining can lead to significant cost savings. The manufacturing process is streamlined, reducing labor and material costs while maintaining high-quality standards. Additionally, the durability of these fabrics means a longer product lifespan, reducing the frequency of replacements and associated costs.

Versatility Across Applications

Foam bonded nonwoven fabrics are exceptionally versatile, finding applications in various sectors including automotive, medical, and consumer goods. Their adaptability to different manufacturing processes makes them an ideal choice for businesses looking to optimize their product offerings.

Cost Efficiency in Production

Cost efficiency is a crucial consideration in any manufacturing process. Foam bonded nonwoven lining excels in this area through several mechanisms.

Reduced Material Waste

The production of foam bonded nonwoven fabrics often results in lower material waste compared to traditional textile manufacturing processes. Efficient bonding techniques minimize off-cuts and excess materials, which can lead to reduced costs and a lower environmental impact.

Lower Labor Costs

Due to the automated nature of the foam bonding process, labor costs can be significantly reduced. Automation not only increases production speed but also decreases the likelihood of human error, ensuring a consistent quality in the final product.

Energy Efficiency

The foam bonding process can also be more energy-efficient than traditional methods. By utilizing less energy during production, manufacturers can further decrease costs while contributing to sustainability goals.

Applications in Various Industries

Foam bonded nonwoven lining is utilized in several industries, showcasing its versatility and effectiveness.

Automotive Industry

In the automotive sector, foam bonded nonwoven fabrics are commonly used in **interior linings, sound insulation,** and **seat padding**. Their lightweight and cushioning properties enhance passenger comfort while also contributing to noise reduction.

Healthcare Sector

The healthcare industry benefits from foam bonded nonwoven materials in products such as **surgical masks, gowns,** and **patient bedding**. These fabrics offer a combination of softness, breathability, and protection, making them ideal for critical applications.

Consumer Goods

From home textiles to clothing, foam bonded nonwoven lining is increasingly being used in consumer goods. It provides added comfort and durability, appealing to manufacturers looking to enhance product performance.

Sustainability Aspect of Foam Bonded Nonwoven

As industries shift towards more sustainable practices, foam bonded nonwoven fabrics have emerged as a favorable option. Many of these fabrics are produced from recycled materials or are themselves recyclable, aligning with global sustainability goals.

Eco-Friendly Production Techniques

Innovations in production techniques have introduced more eco-friendly methods, reducing water and energy consumption. Manufacturers can achieve high-quality outputs while minimizing their ecological footprint.

Biodegradable Options

The development of biodegradable foams and fibers further enhances the sustainability of foam bonded nonwoven fabrics. These options allow manufacturers to meet consumer demand for environmentally responsible products without compromising on performance.

The Future of Nonwoven Fabrics

Looking ahead, the future of foam bonded nonwoven fabrics appears promising. With ongoing research and development, we can expect continual improvements in performance, sustainability, and functionality.

Technological Innovations

Advancements in technology will likely lead to even more efficient production processes and enhanced fabric characteristics. As manufacturers push for higher quality and lower costs, foam bonded nonwoven lining will remain at the forefront of innovation in textiles.

Market Trends

As industries evolve, the demand for high-performance nonwoven fabrics will likely increase. Manufacturers who adapt to market trends and embrace the benefits of foam bonded nonwoven lining will position themselves for success in a competitive landscape.

Conclusion

Foam bonded nonwoven lining presents a remarkable opportunity for manufacturers across various industries to enhance quality while reducing costs. With its unique combination of performance benefits, cost efficiency, and sustainability, this innovative material is set to revolutionize production processes. As the industry continues to evolve, embracing foam bonded nonwoven fabrics will be essential for businesses seeking to maintain a competitive edge.

FAQs

1. What are the main advantages of foam bonded nonwoven lining?

Foam bonded nonwoven lining offers enhanced performance, cost-effectiveness, and versatility across various applications, making it a valuable choice for manufacturers.

2. How does the foam bonding process work?

The foam bonding process involves layering fibers and foam together, then applying heat and pressure to create a cohesive fabric.

3. Which industries utilize foam bonded nonwoven fabrics?

Industries such as automotive, healthcare, and consumer goods make extensive use of foam bonded nonwoven fabrics due to their performance characteristics.

4. Are foam bonded nonwoven fabrics sustainable?

Yes, many foam bonded nonwoven fabrics are produced from recycled materials and can be recycled themselves, aligning with sustainability goals.

5. What future innovations can we expect in foam bonded nonwoven fabrics?

Future innovations may include advancements in production techniques, improvements in fabric properties, and a greater emphasis on sustainability.

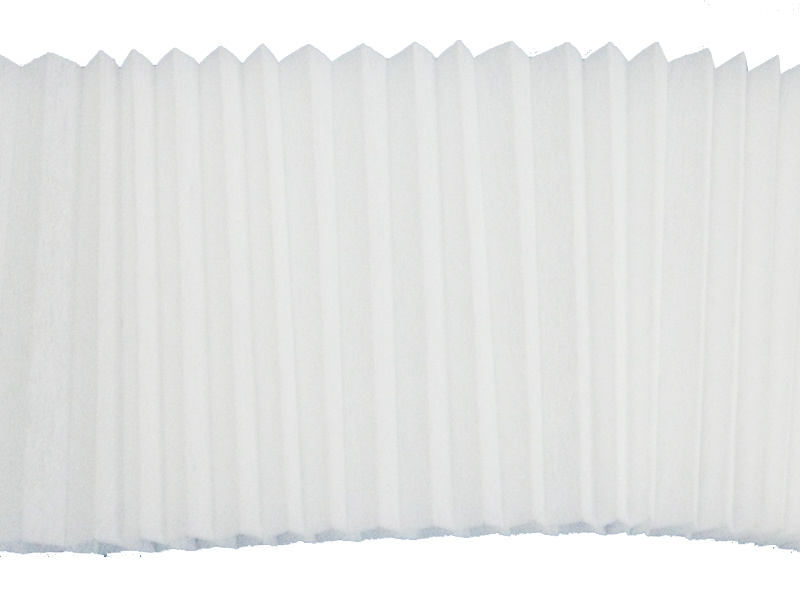

Foam Bonded Nonwoven lining

Latest News

Nantong Rainbow Technology Co., Ltd.

Telephone:+86-13587673537

E-mail:chrislc717@163.com

Address: Group 42, Xizansi Village, Xiting Town, Tongzhou District, Nantong City, Jiangsu Province

Copyright©2024 Nantong Rainbow Technology Co., Ltd. | Powered by www.300.cn

Copyright©2024 Nantong Rainbow Technology Co., Ltd.

Powered by www.300.cn