Understanding Nonwoven Fusible Interlining: A Key Component in Textile Applications

Release time:

2025-07-10

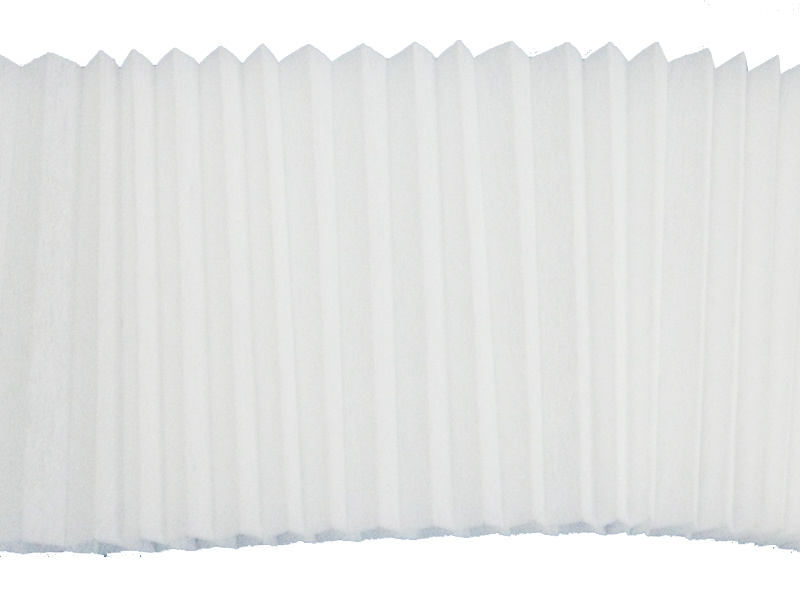

Nonwoven fusible interlining is a critical component in the textile industry, especially when it comes to garment construction and enhancing fabric performance. This specialized material is designed to provide additional support and structure to fabrics, making it indispensable for various applications in fashion and home textiles.

At its core, nonwoven fusible interlining consists of fibers that are bonded together through mechanical, thermal, or chemical means, rather than woven or knitted. This process results in a material that is lightweight yet effective at reinforcing the fabric it is applied to. The fusible aspect of this interlining means that it is coated with a heat-activated adhesive on one side, allowing it to bond seamlessly to another fabric when heat is applied.

One significant benefit of using nonwoven fusible interlining is its ability to enhance the drape and structure of a garment. When applied to areas such as collars, cuffs, and waistbands, it provides a crisp finish and maintains the shape of the fabric over time. This is particularly important in high-quality garments where a polished appearance is crucial.

Moreover, nonwoven fusible interlining is available in various weights and stiffness levels, making it adaptable to different fabric types and end uses. Lightweight interlinings are ideal for delicate fabrics, ensuring that the garment retains its softness and flow, while heavier options offer more support for structured designs. This versatility allows designers and manufacturers to select the appropriate interlining based on the specific requirements of their projects.

Additionally, nonwoven fusible interlining plays a vital role in improving the overall durability of garments. By adding a layer of protection and support, it can help prevent fraying, stretching, and distortion of the fabric, thus extending the life of the finished product. This durability is particularly advantageous for garments that undergo frequent washing and wearing.

In terms of application, the process of attaching nonwoven fusible interlining is straightforward. It typically involves cutting the interlining to the desired shape, positioning it on the fabric, and then applying heat through a press or iron to activate the adhesive. This ensures a secure bond that can withstand the rigors of regular use.

In conclusion, nonwoven fusible interlining is an indispensable material in the textile industry, providing essential support and structure to a variety of garments. Its lightweight nature, adaptability, and durability make it a go-to choice for designers and manufacturers striving for high-quality results. Understanding its properties and applications can empower professionals in the textile field to make informed decisions that enhance their products and meet consumer demands.

At its core, nonwoven fusible interlining consists of fibers that are bonded together through mechanical, thermal, or chemical means, rather than woven or knitted. This process results in a material that is lightweight yet effective at reinforcing the fabric it is applied to. The fusible aspect of this interlining means that it is coated with a heat-activated adhesive on one side, allowing it to bond seamlessly to another fabric when heat is applied.

One significant benefit of using nonwoven fusible interlining is its ability to enhance the drape and structure of a garment. When applied to areas such as collars, cuffs, and waistbands, it provides a crisp finish and maintains the shape of the fabric over time. This is particularly important in high-quality garments where a polished appearance is crucial.

Moreover, nonwoven fusible interlining is available in various weights and stiffness levels, making it adaptable to different fabric types and end uses. Lightweight interlinings are ideal for delicate fabrics, ensuring that the garment retains its softness and flow, while heavier options offer more support for structured designs. This versatility allows designers and manufacturers to select the appropriate interlining based on the specific requirements of their projects.

Additionally, nonwoven fusible interlining plays a vital role in improving the overall durability of garments. By adding a layer of protection and support, it can help prevent fraying, stretching, and distortion of the fabric, thus extending the life of the finished product. This durability is particularly advantageous for garments that undergo frequent washing and wearing.

In terms of application, the process of attaching nonwoven fusible interlining is straightforward. It typically involves cutting the interlining to the desired shape, positioning it on the fabric, and then applying heat through a press or iron to activate the adhesive. This ensures a secure bond that can withstand the rigors of regular use.

In conclusion, nonwoven fusible interlining is an indispensable material in the textile industry, providing essential support and structure to a variety of garments. Its lightweight nature, adaptability, and durability make it a go-to choice for designers and manufacturers striving for high-quality results. Understanding its properties and applications can empower professionals in the textile field to make informed decisions that enhance their products and meet consumer demands.

Nonwoven fusible interlining

Latest News

Nantong Rainbow Technology Co., Ltd.

Telephone:+86-13587673537

E-mail:chrislc717@163.com

Address: Group 42, Xizansi Village, Xiting Town, Tongzhou District, Nantong City, Jiangsu Province

Copyright©2024 Nantong Rainbow Technology Co., Ltd. | Powered by www.300.cn

Copyright©2024 Nantong Rainbow Technology Co., Ltd.

Powered by www.300.cn