The Comprehensive Guide to the Benefits of Dustproof Nonwoven Air Filters in the Textile Industry

Release time:

2025-06-13

The Comprehensive Guide to the Benefits of Dustproof Nonwoven Air Filters in the Textile Industry

Table of Contents

1. Introduction to Nonwoven Air Filters

2. Understanding Dustproof Nonwoven Air Filters

3. Key Benefits of Using Dustproof Nonwoven Air Filters

3.1 Improved Air Quality in Textile Manufacturing

3.2 Enhanced Worker Health and Safety

3.3 Increased Production Efficiency

3.4 Cost-Effectiveness and Longevity

3.5 Environmental Impact and Sustainability

4. Applications of Nonwoven Air Filters in the Textile Sector

5. Selecting the Right Nonwoven Air Filter

6. Best Practices for Maintenance and Use

7. Future Trends in Nonwoven Air Filtration Technology

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Introduction to Nonwoven Air Filters

In the textile industry, where the production process generates substantial dust and airborne particles, maintaining air quality is crucial. Dustproof nonwoven air filters are engineered to capture these particulates effectively, ensuring a cleaner environment for both equipment and personnel. As we delve deeper into the advantages of these filters, it becomes evident how they play a vital role in enhancing productivity and safeguarding health.

2. Understanding Dustproof Nonwoven Air Filters

Dustproof nonwoven air filters are made from synthetic fibers that are bonded together through mechanical, thermal, or chemical processes. This unique structure provides a highly efficient barrier against dust, lint, and other airborne contaminants. Their design allows for a higher surface area, enabling better airflow while trapping harmful particles. This innovative solution is particularly beneficial for the textile industry, where the presence of fine fibers and dust can significantly impact operational efficiency.

3. Key Benefits of Using Dustproof Nonwoven Air Filters

3.1 Improved Air Quality in Textile Manufacturing

One of the most significant advantages of implementing dustproof nonwoven air filters is the improvement in air quality. By effectively capturing a wide range of pollutants, these filters help maintain a cleaner atmosphere within manufacturing facilities. This not only benefits the machines, reducing wear and tear but also significantly enhances the overall working environment for employees.

3.2 Enhanced Worker Health and Safety

Dust and particulate matter can lead to various health issues among workers, including respiratory problems and allergic reactions. By utilizing dustproof nonwoven air filters, textile manufacturers can significantly mitigate these risks, promoting better health and safety standards. A cleaner air environment fosters a productive workforce, reducing absenteeism and increasing employee satisfaction.

3.3 Increased Production Efficiency

A clean production environment translates directly into increased efficiency. When machines are free from dust accumulation, they operate more effectively, leading to fewer breakdowns and maintenance issues. Dustproof nonwoven air filters facilitate this process by ensuring that the air machinery breathes remains clean, resulting in smoother operations and higher output.

3.4 Cost-Effectiveness and Longevity

Investing in dustproof nonwoven air filters can lead to long-term savings. Their durability and efficiency reduce the need for frequent replacements, unlike traditional filters that clog quickly and require regular changes. This cost-effectiveness extends to maintenance expenses as well, as cleaner environments lead to fewer equipment repairs.

3.5 Environmental Impact and Sustainability

With increasing awareness around environmental issues, adopting eco-friendly practices is essential for the textile industry. Dustproof nonwoven air filters are often made from recyclable materials, contributing to sustainability efforts. Their efficiency in trapping pollutants also prevents them from entering the atmosphere, aligning with environmental regulations and corporate responsibility goals.

4. Applications of Nonwoven Air Filters in the Textile Sector

Nonwoven air filters are versatile and can be used in various areas within the textile industry. They are commonly utilized in:

- **Spinning Mills**: To capture fine fibers released during the spinning process.

- **Weaving and Knitting Mills**: Where airborne particles can impact the quality of the finished product.

- **Dyeing and Finishing**: To filter out chemicals and dyes that can contaminate the air.

- **General Manufacturing Facilities**: Improving overall air quality throughout the production process.

5. Selecting the Right Nonwoven Air Filter

Choosing the appropriate dustproof nonwoven air filter involves several considerations:

- **Particle Size and Type**: Understand the specific contaminants present in your facility.

- **Airflow Requirements**: Ensure the filter can handle the air volume required for your operations.

- **Filter Efficiency Ratings**: Look for filters with high Minimum Efficiency Reporting Value (MERV) ratings for optimal performance.

Consulting with suppliers and industry experts can provide valuable insights into the best choices for your specific needs.

6. Best Practices for Maintenance and Use

To maximize the effectiveness of dustproof nonwoven air filters, regular maintenance is essential. Here are some best practices:

- **Routine Inspections**: Regularly check filters for signs of wear or clogging.

- **Scheduled Replacements**: Follow manufacturer guidelines for replacing filters to maintain efficiency.

- **Clean Surrounding Areas**: Ensure the environment around the filters is kept clean to reduce external contaminants.

Implementing these practices helps ensure that the filters operate at peak performance, safeguarding air quality consistently.

7. Future Trends in Nonwoven Air Filtration Technology

As technology evolves, so does the development of nonwoven air filters. Future trends may include:

- **Smart Filtration Systems**: Integrating IoT technology for real-time monitoring and alerts for filter replacement.

- **Nanotechnology**: Enhancements to filter materials that improve particle capture efficiency.

- **Biodegradable Materials**: Increased focus on sustainability with filters made from eco-friendly, biodegradable fibers.

These innovations will continue to shape the future of air filtration in the textile industry, driving efficiencies and environmental responsibility.

8. Frequently Asked Questions (FAQs)

What makes nonwoven air filters different from traditional filters?

Nonwoven air filters use a web of synthetic fibers that provide a higher surface area for trapping dust and particulates, allowing for better airflow and efficiency compared to traditional woven filters.

How often should dustproof nonwoven air filters be replaced?

Replacement frequency depends on usage and environmental conditions, but regular inspections should be conducted to ensure optimal performance.

Can nonwoven air filters be recycled?

Many nonwoven air filters are made from recyclable materials. It's advisable to check with manufacturers for specific recycling instructions.

What are the health benefits of using dustproof nonwoven air filters?

These filters significantly reduce airborne contaminants, leading to better air quality and reduced health risks, including respiratory problems and allergies among workers.

How do nonwoven air filters contribute to sustainability in the textile industry?

They help minimize waste and emissions by capturing pollutants and are often made from recyclable materials, promoting eco-friendly practices.

9. Conclusion

The integration of dustproof nonwoven air filters in the textile industry stands as a pivotal advancement that enhances air quality, promotes worker health, and increases operational efficiency. By making informed choices about air filtration, textile manufacturers can reap numerous benefits while also committing to sustainable practices. As we look to the future, continued innovation in this field promises even greater advancements, ensuring that the textile industry can operate more safely and effectively. Embracing these technologies not only bolsters production but also fosters a healthier working environment, ultimately leading to a more sustainable future for all stakeholders involved.

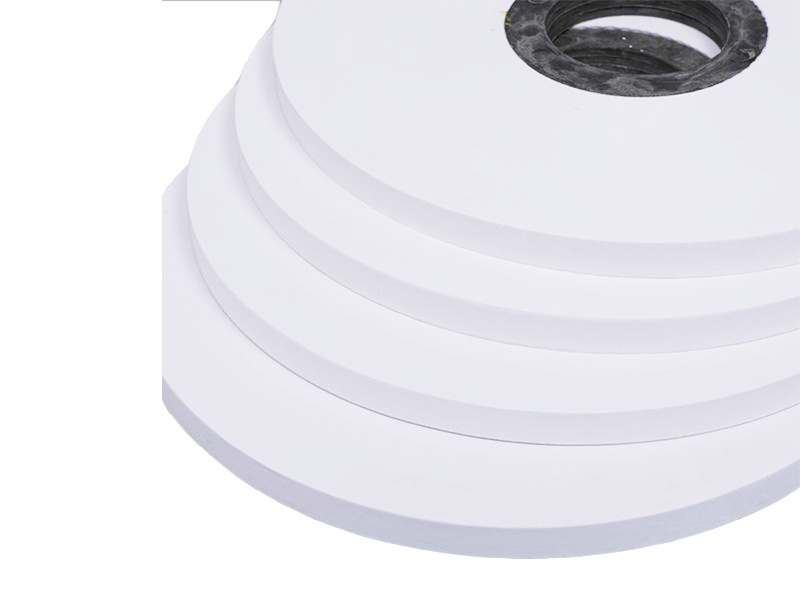

Dustproof Nonwoven Air Filter

Latest News

Nantong Rainbow Technology Co., Ltd.

Telephone:+86-13587673537

E-mail:chrislc717@163.com

Address: Group 42, Xizansi Village, Xiting Town, Tongzhou District, Nantong City, Jiangsu Province

Copyright©2024 Nantong Rainbow Technology Co., Ltd. | Powered by www.300.cn

Copyright©2024 Nantong Rainbow Technology Co., Ltd.

Powered by www.300.cn