Air filtration series

Classification:

Key words:

Air filtration series

Product Consulting

Product Consulting

Product Details

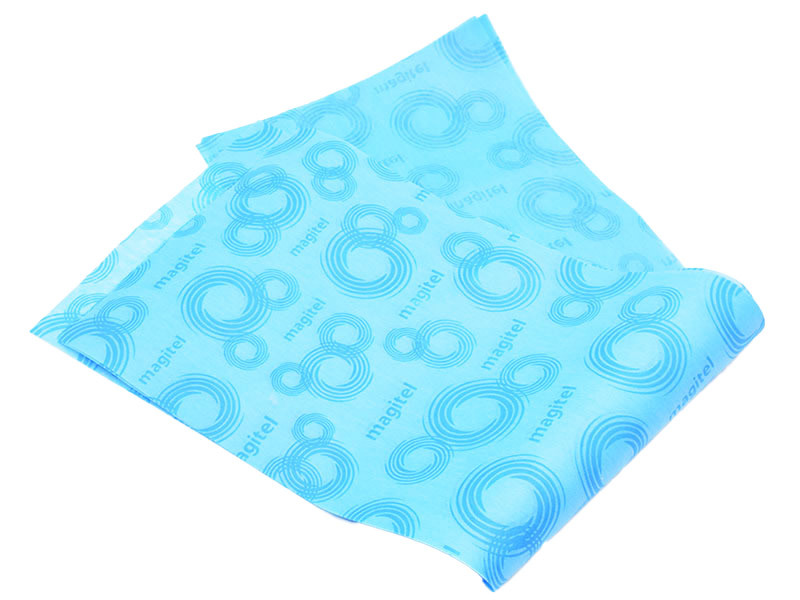

Meltblown Nonwoven for Air Filtration plays an extremely important role in the field of air filtration.

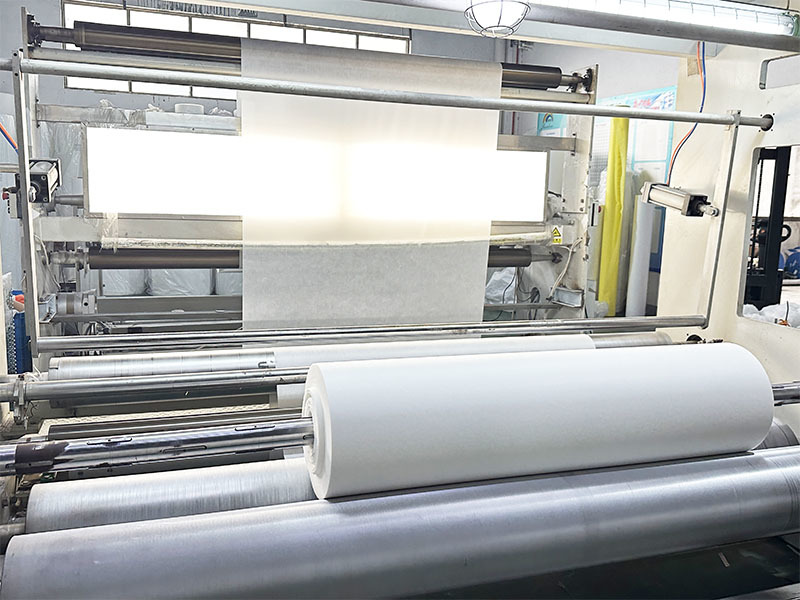

1. Materials and Manufacturing Process

Meltblown Nonwoven for Air Filtration uses polymer chips as raw materials. After high-temperature melting, it is extruded through the spinneret hole and stretched by high-speed hot air to form extremely fine fibers. These fibers are then condensed and laid on the collection device to form non-woven fabrics. This process can produce materials with very small fiber diameters, laying the foundation for its excellent filtration performance.

2. Product Features

High-efficiency filtration

The fiber diameter can be as small as micron level, which gives it an extremely high specific surface area. When filtering air, it can effectively intercept tiny particles in the air, such as dust, pollen, bacteria and even some viruses. It has excellent filtration efficiency for tiny pollutants such as PM2.5, which can greatly improve air quality.

Good air permeability

Despite its good filtration effect, Meltblown Nonwoven for Air Filtration does not hinder the normal circulation of air. Its fiber structure allows air to pass smoothly while intercepting impurities, ensuring that ventilation systems or respiratory protective equipment have sufficient air exchange during use.

Lightweight and portable

It is lightweight and does not add too much weight when manufacturing air filtration products. This feature makes it popular in portable air purifiers, masks and other products, making it convenient for users to carry and use for a long time.

3. Application Scope

In industrial air purification systems, Meltblown Nonwoven for Air Filtration is widely used to filter impurities in the intake air and protect equipment. In the medical and health field, it is the core filter layer of the mask, providing key protection for people against harmful microorganisms; in home air purifiers, it also plays an important role in core filtration.

Intelligent workshop

Roll up machine

Cut and roll

Import production line

Domestic advanced production line

Warehouse

Warehouse

Transport

Packaging and transportation

Modern factory area

Process flow

Feeding

Blending

Carding

Impregnating

Drying

Rolling

Slitting and rewinding

Packaging and transportation

Exhibition and team

Qualification Certification

recommend products

online message

If you have any suggestions, please leave a message or send an email to us, and we will reply to you within 1 working day after receiving the message email.

Nantong Rainbow Technology Co., Ltd.

Telephone:+86-13587673537

E-mail:chrislc717@163.com

Address: Group 42, Xizansi Village, Xiting Town, Tongzhou District, Nantong City, Jiangsu Province

Copyright©2024 Nantong Rainbow Technology Co., Ltd. | Powered by www.300.cn

Copyright©2024 Nantong Rainbow Technology Co., Ltd.

Powered by www.300.cn